Cargo sampling

Cargo sampling

Goods cargo sampling is the taking and retention of actual representative (random) samples of goods in international trade, the purpose of which is to verify quality specifications.

Sampling locations: AIM Group's inspectors can collect samples from all points in the supply chain, from mines to warehouses, docks, barges, ships, pipelines or service stations.

Purposes of sampling

The top of importance in sampling

The handling of cargo samples, Cargo samples hold significant importance in protecting right of each party against potential cargo claims, necessitating the utmost care in their proper handling.

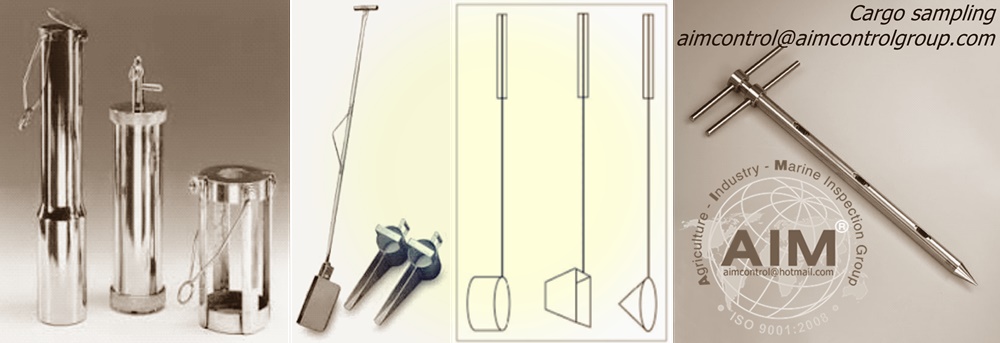

For Cargo and liquid sampling in shipping:

Cargo samples hold significant importance in protecting various ship owners against potential cargo claims from shippers, receivers and third party. That's reason, AIM Group is always strict in terms of sampling procedure process, sampling tools, sampling experts, sampling standards, etc. . .

Type of sample bottles (Material, color, Volume)

Regarding the nature of the goods, choose the type of material to contain the sample.

For example:

Pure acids or basic cargoes should be kept in plastic bottles (type HDPE). Do not use glass material.

The acids products will deteriorate glass over time resulting in the product containing increased levels of silica (e.g., sand or glass), but also because the bottles will become brittle and may break easily after a period of storage.

Inhibited and light sensitive cargoes are often stored in amber bottles. But if the samples are stored in dark sample lockers, then transparent bottles can be considered. Furthermore, quality complaints typically concern parameters that are not affected by light.

For vegetable oils (and other food grade products) transparent plastic or glass bottles should be used (of a type which doesn't shrink under the effect of heated cargo)

Labeling and log keeping:

The label must contain, at a minimum, the following information:

-

Ship name and trip number (or shipment, container)

-

Type of goods, loading and unloading port

-

Sample details (Cargo hold, location, piping, initial, final, etc.)

-

Date and name of person who took it.

-

Weight and volume

-

Seal number

-

Sample type

-

Seller/recipient name

Sampling of records made in the Port Log may also be used as evidence.

Retention time:

The period of retention for samples, disposing of them after a claim is arisen against the vessel. (about 6 or 12 months from the date of delivery).

Cargo surveyors for sampling:

The important is clarify the role of AIM Group's cargo surveyors:

1. Never advise for Master or C/O for issuing Letters of Protest for "failure to draw samples for the vessel"

2. Involved in the sampling process. 24/24 in witness and take samples to be with the any party's cargo surveyors represent

3. No following and do instructions from other, which may differ from the vessel's interests or our customer. (this can result in a lack of samples or disagreements regarding the representation of available samples).

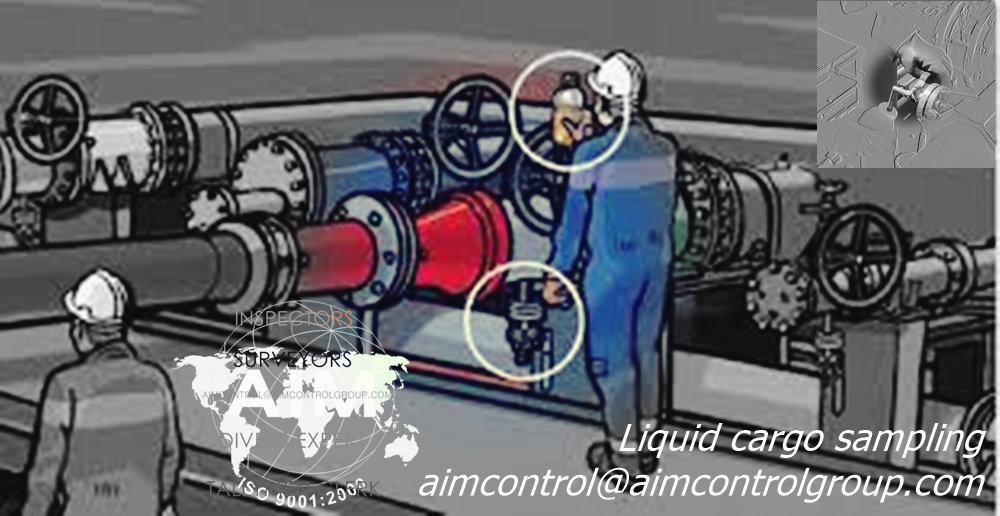

In case, cargo is liquid, the samples from cargo tanks, shore tanks or drums must be taken at 3 levels, bottom, middle and top in order to represent all cargo inside tank.

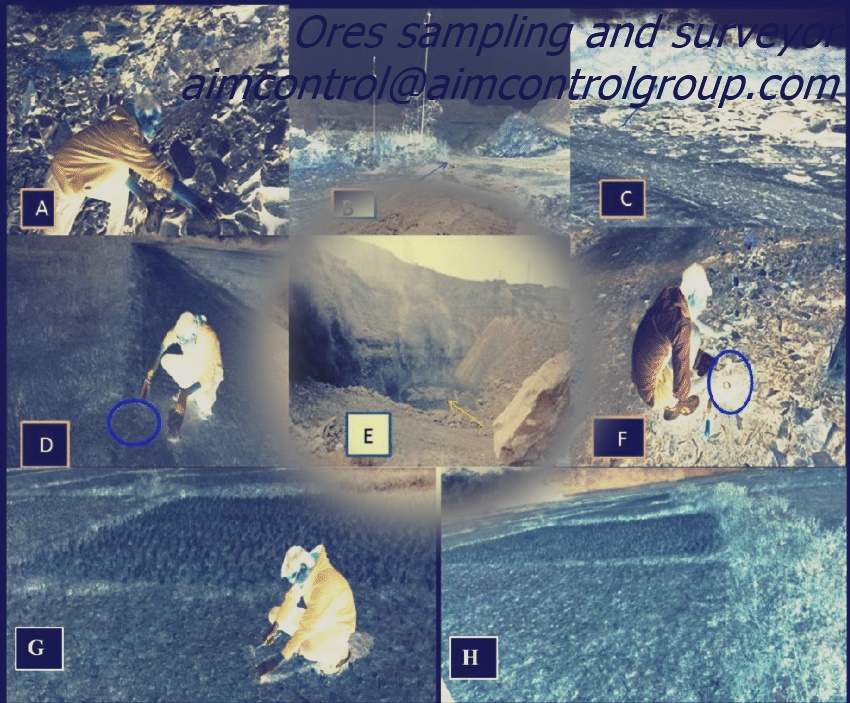

For Ore sampling at mine and for shipping:

At mine:

What is ore sampling?:

The process in which a portion (sample of ore) is selected in such a way, that its composition will represent the average composition of the entire bulk of ore. Such a selected portion is a sample, and the art of properly selecting such a sample is called sampling.

What is the sampling method of mining?:

Sampling is performed by the cutting of channels across a mineralized body in fresh surface exposures or underground mine workings, such as the mine face, walls, and roof. The area is cleaned to remove dust, dirt, slime, and soluble salts by any of three processes.

How is ore collected?:

The ore and the gangue are mined together—i.e., taken out of the host rock in a mass by either mechanical or manual means. Then the ore is separated from the gangue by various operations known collectively as mineral processing, or ore dressing.

What are the methods of sampling?:

There are various major types of sampling methods: probability and non-probability sampling. Probability sampling, also known as random sampling, is a kind of sample selection where randomisation is used instead of deliberate choice. Each member of the population has a known, non-zero chance of being selected.

The sampling: Random, Systematic, Convenience, Cluster, and Stratified. Random sampling is analogous to putting everyone's name into a hat and drawing out several names.

Why is sampling important in mining?:

Sampling can also measure how the environment is changing over time. Data from sampling is necessary to understand how mining activities and mine waste changes the environment.

At ship and yard of port:

Sampling should take into account the following factors:

Type of material:

Manner in which the material is stored, in stockpiles, rail wagons or other containers and transferred or loaded by material-handling systems such as conveyors, loading chutes, crane grabs etc.

The characteristics which need to be determined: MC, TML, bulk density/stowage factor, angle of repose etc.

Variations in moisture distribution throughout the consignment which may occur due to weather conditions, natural drainage, e.g., to lower levels of stockpiles or containers, or other forms of moisture migration, and

Variations which may occur following freezing of the material.

Where international or nationally accepted standard procedures are in-place for specific commodities, these should be followed. In the absence of such standards, the IMSBC Code makes the following

recommendations in Section 4.6.4 of the Code; “The number of sub-samples and sample size are given by the competent authority or determined in accordance with the following scale:

-

Consignments of not more than 15,000 t: One 200g sub-sample is taken for each 125 t to be shipped.

-

Consignments of more than 15,000 but not more than 60,000 t: One 200g sub-sample is taken for each 250 t to be shipped.

-

Consignments of more than 60,000 t: One 200g sub-sample is taken for each 500 t to be shipped.”

Stockpiles:

Establish the quantity of ore in the stockpile either directly from the shipper’s representatives or by estimating the length, width and height of the pile from which to calculate the overall volume and assume a density of about Xx MT/M3.

From the quantity of ore, determine the number of sub-samples required from the scale above and then mentally divide the pile into separate smaller sections to simplify the process of sampling.

Calculate the number of sub-samples to be drawn from the smaller sections of the pile and plan precisely from which parts each sub-sample will be taken.

Barges:

After establishing the quantity of ore onboard the barge, determine the total number of sub-samples required and divide the stow up into smaller sections. For each section, plan the sampling points so as to obtain the requisite number of sub-samples spread across the area concerned.

Cargo stows in ship’s holds:

Determine the required number of sub-samples on the basis of the quantity of cargo in the hold and the scale given above.

As a minimum, each sub-sample should be drawn from manually excavated pits of 50cm depth and care should be taken to ensure that no surface material is admixed. If the vessel is geared, then five pits should be excavated – four in the corners and one in the centre of the hold and samples drawn from each pit at varying levels from 50cm under the surface down to the level of the tank top if at all possible.

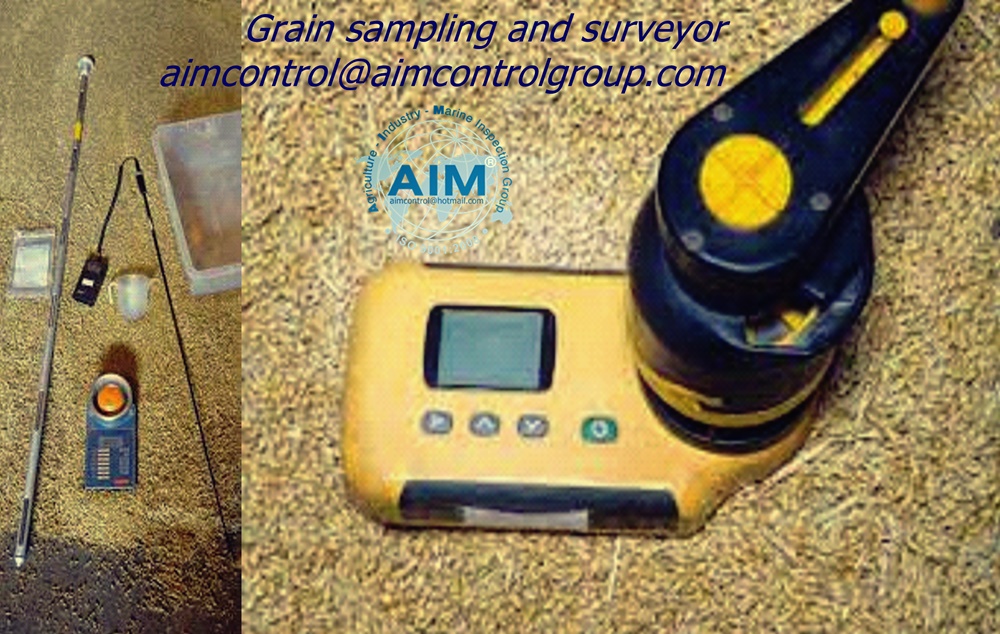

For Goods, Foods and Commodity Other

Based on each cargo and its relation, AIM Group will calculate and perform the sampling in suitable and standards.

Referring to our “Can Test”