Product quality inspection

Product quality inspection

AIM Control (AIM Group®)

-

Audit the ability of a factory to produce

-

Verification the product standards that meet the market

-

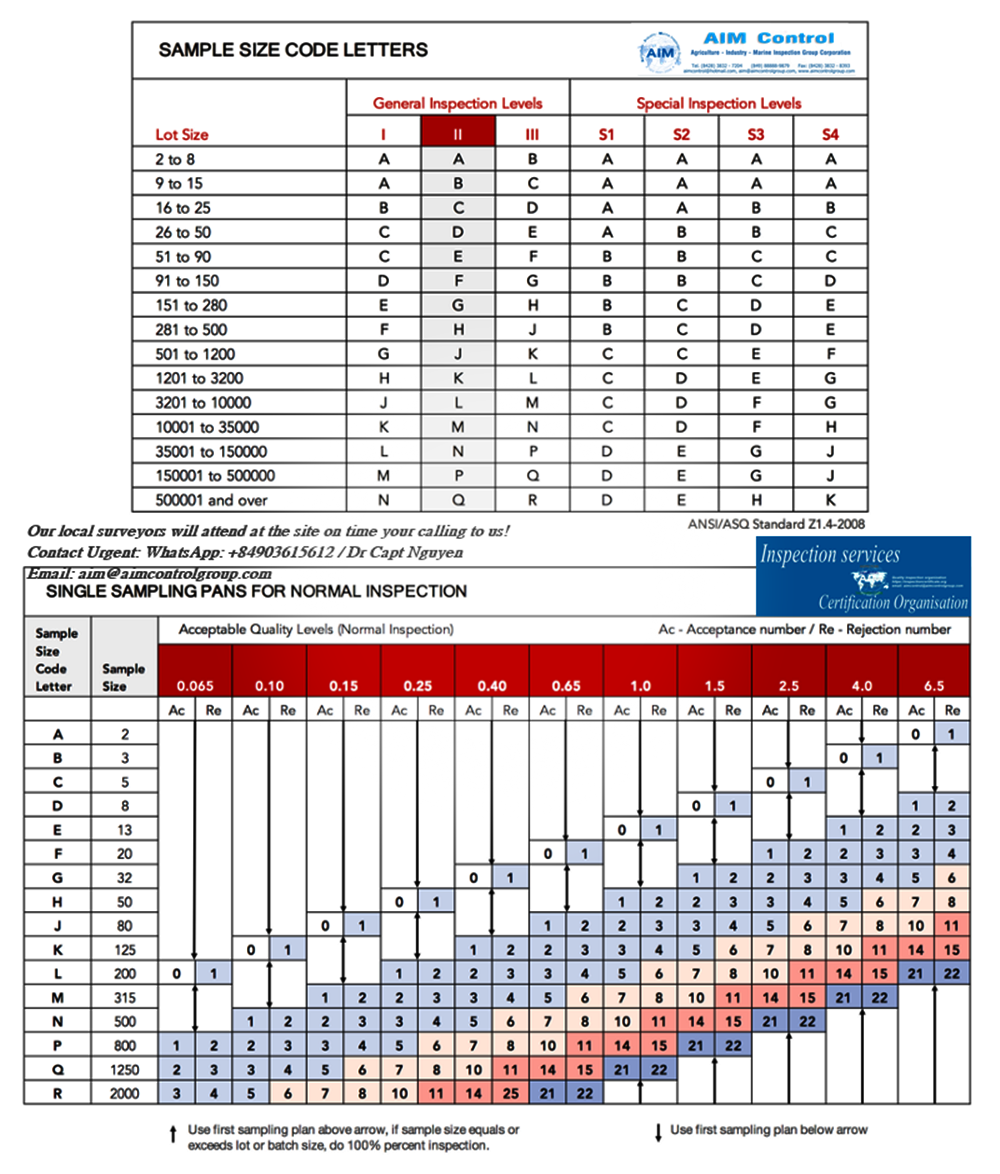

Sampling of material / product

-

Analysis and testing of raw materials / products

-

Product manufacturing monitoring

-

Inspection and measurement of product dimensions

-

Checking of product function

-

Identifying of product quality

-

Surveillance of product assembly and synchronization of system

-

Tallying of product quantity.

-

Checking packaging specifications.

-

Product classification inspection (by standards)

-

Supervision of loading products into pallets / vehicles / container / ship

-

Inspection of unloading of products.

-

Other industrial expertise

See more

-

Product quality inspection services in heavy industry of steel

-

Quality inspection services in processing Agriculture products and commodity

-

Quality assurance services in hand-made of consumer goods and foodstuffs

Product quality inspection and standard quality certification services

The AIM Inspection Body will determine the quality and quantity of products according to predetermined standard specifications. The reduction of defects and savings in production costs and period to market are beneficial for businesses to increase their competitive position in providing comprehensive quality products in a timely and effective manner reputation.

A product that does not meet your quality specifications in standards is placed on the market for disqualification, which can result in lost brand, product and revenue, delayed delivery, wasted materials and risk. Its products to be recalled and many other risks!

At AIM, the purpose of quality inspection is to "Detect and Eliminate Defects to optimize the best quality advantage" to meet the requirements of all customers.

1- Issuance of standard quality inspection certificates to meet different markets for buyers, sellers and users. . .

2- product range for which AIM provides inspection and certification services:

2.1 - Agricultural products and food

2.2- Industrial machinery equipment

2.3- Goods Consumables and Foods

2.4- Ships and marine equipment

2.5- Machinery and equipment for oil and gas industry

2.7- Wood and furniture

2.8- Medical equipment and state public works projects

2.9- Other products and equipment not in the above industries.

3- Surveyors, offices and branches: in provinces and cities at home and abroad.

4- Laboratory and analysis: at AIM and laboratory system and Worldwide partners are certified to international standards and according to customer requirements. (In addition, AIM Group cooperates with analysis and testing laboratories of each country, inspection units in the same industry such as SGS, BV, TUV . . . and specialized laboratories for specific products of each country, a factory to produce and process products to best serve customers' requirements).

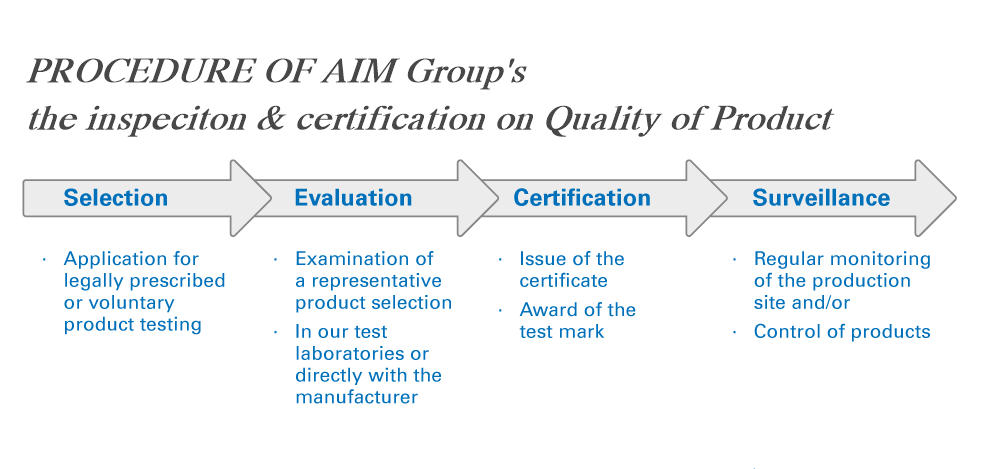

Quality inspection process Basic qualification includes five main steps. Depending on the product, your agreement with the supplier and other factors that shape the need for inspection, quality criteria and parameters to be analyzed, tested and certified.

Pre-production inspection (PPI) / Material quality control

Prior to production, quality testing of raw materials and components will confirm that they meet specifications and are in sufficient quantity to meet production schedules. This is a very useful service when a business is having problems with replacement materials and/or components, or they are working with a new supplier and need a lot of components and materials from outside sources within the production process. In addition, the quality inspection of the machine system, equipment, lines and assessment of technicians, workers' skills and factory quality management system is extremely necessary!

Depending on the strictness and rigor of each different market, the products that are distributed, will have their own regulations and standards! Supply companies, sellers, and manufacturers must find out “who their products will sell to and in which markets”!

In-process inspection (DPI)

During production, products are tested to verify that they meet quality requirements and specifications. This process is useful in the event of repeated manufacturing failures. It can help identify where problems occur in the process and provide an unbiased view of how to find solutions to production problems.

Manufacturing enterprises must “know” the following factors:

1- market and consumer standards

2- Buyer's request

3- customer and consumer feedback

4- good products of competitors

5- Laws of countries and territories

6- Opinions of employees and quality process controllers

7- third party quality inspection results (AIM Group)

8- other information channels

Pre-shipment inspection (PSI)

After production is completed, a pre-shipment inspection is carried out to verify that the goods have been manufactured in accordance with the requirements. This is the most commonly chosen service and works well for the suppliers that the business has worked with before.

Random Inspection (or Classification Inspection)

Inspection of each type of goods can be done before or after packing. This service is performed on the entire item to evaluate the general appearance, sophistication, function, safety, etc. as specified by the business.

Container Loading Monitoring (LS)

AIM's technical staff will supervise the entire process of inspecting the condition of the container (or the suitability of the means of transport) loading the container, certifying lashing and dangerous goods and explosion-proof. We will check to ensure that the order is complete and securely packed into the container (or transport vehicle) and certify for transport prior to delivery. This form is intended to confirm compliance with your requirements for quantity, type and packaging and safety in shipping from the port of departure to the port of destination (or transshipment).

Benefits of Product Quality Inspection at AIM Group

Quality inspection at different stages of the manufacturing process can help assess and control the quality of products, to ensure they meet requirements and are delivered on time. With the right quality inspection systems, processes and procedures, AIM will help businesses reduce risks, improve efficiency and ensure compliance with contractual or regulatory requirements, building a business. stronger and more flexible with the potential to grow and surpass the competition.

Consumers and Customers will buy qualified products that are beneficial to health and safety

-

Make sure every process goes well at every stage of production

-

Quality inspection at the source and no payment if the goods are defective

-

Avoid product recalls and reputational damage

-

Anticipate possible delays in production and delivery

-

Helps to reduce the budget for product quality inspection

Other quality inspection services:

Sample review Classification inspection

Product Safety Inspection (ex: Metal Detection)

Supervision of loading/unloading

Why is Quality Inspection important?

Expectations about the quality and range of safety requirements that businesses need to meet are becoming increasingly complex. If a product fails to meet quality expectations in the marketplace, the results can be lost goodwill, products, revenue and customers, delayed deliveries, wasted materials, and the risk of recalls product. AIM has the network global systems, processes and procedures in place to help you meet your requirements and deliver quality products in quick time.

Why choose AIM?

Established in 1993, headquartered in Vietnam and a leading Independent Inspection Organization in 05 continents, AIM has in-depth knowledge of quality control systems and processes, as well as achieving all necessary certifications like CNAS, CMA, GACC, IFIA, GAFTA, FOSTA, CITEC, ICA, FIATA, IATA, PIFFA, ASTM, ACCAP & ISO, TCVN, and National Standards etc. 2,500 professionals in more than 100 countries, we are able to organize inspection services in Asia and anywhere in the world within 48 hours, and provide an Inspection Report within 24 hours thereafter. No matter the industry, textiles, toys and baby products, footwear, hard goods, food, electronic and electrical products, home appliances, automobiles, construction, machinery and equipment, shipping and oil and gas industry equipment, whether commercial or consumer goods, AIM can always help you meet the quality, safety and ethical standards you require throughout its supply chain, thereby improving its competitiveness and efficiency in the global marketplace. Main content of quality inspection process

After issuing “The quality inspection certificate”, AIM always provides after-sales service to customers through “Advice and consulting”

`

At the claim and loss issues, AIM’s professional surveyors will have done the roles in solving for the customer

Third party inspection organization

Best Regards

Dr Capt. Nguyen Te Nhan / G.D

Agriculture Industry Marine Control Inspection Group of Companies®

-------------

E-mail: CEO@aimcontrolgroup.com

inspection@aimcontrolgroup.com

diving@aimcontrolgroup.com

qualitycontrol@aimcontrolgroup.com

tallying@aimcontrolgroup.com

MSN : aimcontrol@hotmail.com

http://www.inspectioncertificate.org

https://www.aimcontrolgroup.com

Tally Survey Inspection Certification Investigation Expertise Witness

Diving Underwater Clean Warranty & Approval Asia, Global.

Surveyors I Inspectors I Consultant I Tally-men I Divers I Experts

Other activity :

- Timber Wood quality inspection

- Crude and refined oil cargo test and inspection

- Boat Yacht quality inspection and discharging loading survey

- Consumer Goods quality assured inspection

- Zinc Oxide quality inspection and loading discharging supervision

- Freight Inspection of transport goods

- Cargo Pre-shipment Survey and Loading Tally Supervision

- Break bulk project survey

- Sugar in bags inspection vs loading supervision

- Container loading supervision